MIXING GAS SYSTEM

MIXING GAS SYSTEM

INSPIRATOR TYPE LPG-AIR MIXING

INSPIRATOR TYPE LPG-AIR MIXING

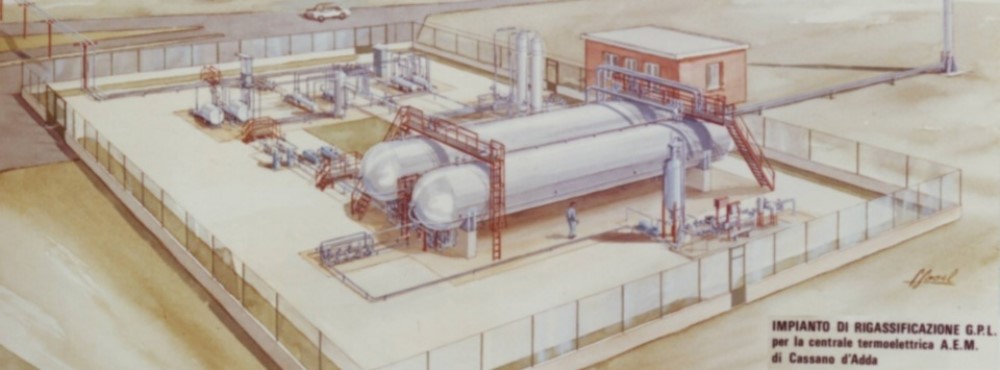

NG-AIR MIXING SYSTEM, AT AIR ASPIRATED, AT VARIABLE FLOW RATE, OF INTEGRATION OR REPLACEMENT OF GAS REFORMING, FOR DISTRIBUTION NETWORK SERVING TOWN. Mixture 11,000 scm/h 25.6 MJ/ncm 35 mbar

NG-AIR MIXING SYSTEM, AT AIR ASPIRATED, AT VARIABLE FLOW RATE, OF INTEGRATION OR REPLACEMENT OF GAS REFORMING, FOR DISTRIBUTION NETWORK SERVING TOWN. Mixture 11,000 scm/h 25.6 MJ/ncm 35 mbar

MIXING NG-GAS BLAST FURNACE, AT GAS ASPIRATED, AT VARIABLE FLOW RATE, OF INTEGRATION OR REPLACEMENT OF COKE OVEN GAS. Mixture 26,000 scm/h 29.3 MJ/ncm 38 mbar

MIXING NG-GAS BLAST FURNACE, AT GAS ASPIRATED, AT VARIABLE FLOW RATE, OF INTEGRATION OR REPLACEMENT OF COKE OVEN GAS. Mixture 26,000 scm/h 29.3 MJ/ncm 38 mbar

NG-AIR MIXING, AT AIR ASPIRATED, VARIABLE FLOW RATE, IN THE REPLACEMENT OF THE GAS CITY A , FOR DISTRIBUTION NETWORK SERVING TOWN. Mixture 5,000 smc/h 18.8 MJ/nmc 16 mbar

NG-AIR MIXING, AT AIR ASPIRATED, VARIABLE FLOW RATE, IN THE REPLACEMENT OF THE GAS CITY A , FOR DISTRIBUTION NETWORK SERVING TOWN. Mixture 5,000 smc/h 18.8 MJ/nmc 16 mbar

NG-AIR MIXING AT SYSTEM, AIR ASPIRATED, VARIABLE FLOW RATE. Mixture 1,500 scm/h 18.8 MJ/ncm 16 mbar

NG-AIR MIXING AT SYSTEM, AIR ASPIRATED, VARIABLE FLOW RATE. Mixture 1,500 scm/h 18.8 MJ/ncm 16 mbar

BUTANE-AIR MIXING SYSTEM, AIR BLOWN, INSTRUMENTAL. MIXTURE 1,750 scm/h 56,52 MJ/ncm 2 bar

BUTANE-AIR MIXING SYSTEM, AIR BLOWN, INSTRUMENTAL. MIXTURE 1,750 scm/h 56,52 MJ/ncm 2 bar

CALORIMETERS THE PERIOD 1960 - 1970

CALORIMETERS THE PERIOD 1960 - 1970

MIXTURES GAS-AIR OR GAS-GAS

In countries where the gas urban distribution service does not exist yet, in order ot anticipate or while waiting for the methane , or where it is not possible or convenient to carry the NG, a good alternative is the distribution of the mixture LPG-air (SNG) interchangeable with the NG.

In countries where there is a refinery, the possibility of using the uncondensable gas of refinery allows it to serve the urban distribution of the gas with a mixture uncondensable refinery gas/air interchangeable with the NG.

In the industries which feature poor process gas (low calorific value), these gases can be used mixing them with NG or LPG.

In the case of urban gas distribution (domestic or industrial uses), in order to cut the peak load at certain times or for lack of reliability of supply of NG, it is economic to integrate by using a mixture of LPG-air with a spare drive in standby.

The interest about those mixtures is mainly addressed to:

- LPG-air with Wi (Wobbe index lower) between 45.8 and 55.3 MJ/sm3, interchangeable with the NG, mostly propane-air mixture with 53,5 MJ/sm3;

- NG-air with Wi between 22.7 and 30.3 MJ/sm3, interchangeable with the town gas;

- the values of Wi of such mixtures are determined in order to carry out a complete interchangeability of the gas to be replaced.

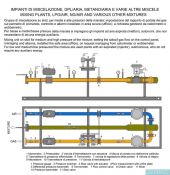

MIXING SYSTEMS GAS/AIR OR GAS/GAS

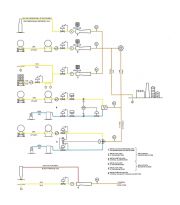

The typology of systems for the production of these gas-air mixtures can be identified into two types:

- Air or gas suction in case of low pressure of the mixture, consisting of a battery of injectors which use the energy of the same gas;

- Air or gas blown in case of medium and high pressure of the mixture, in which for blending both fluids must be available under pressure (air and gas in pressure). The plants for the production of mixtures should produce a mixture with constant calorific value, avoiding possible production of explosive mixtures and also ensure a regulation of the flow.

For low and medium pressures of the mixture, having available the primary fluid with sufficient pressure, the injectors are apt for the task. Pressures up to 0.6 bar for mixtures LPG-air with gross heat value of combustion of 1,438 Btu/cuft.

The venturi mixers give the following advantages:

- use of the energy available in the gas to aspire the air in a safe way, since the lack of pressure in the fluid interrupts the aspiration of the aspired fluid;

- production of a mixture at a constant ratio, maintaining constant the motor fluid pressure and the output pressure.

For medium and high pressure of the mixture, systems with secondary fluid blown are used. In these cases, it is necessary that both fluids are in pressure.

Two solutions are suitable:

- instrumental system, consisting of two lines of measurement with instrumentation for regulation and control;

- mixing valve Procomix, which ensures a perfect mixing ratio with the varying of the Mixing valve Procomix.

The mixing valve is constituted by the body provided with two opposite openings, one for the placing of a fluid (gas) and the other for the placing of the fluid to be mixed. Inside, a movable cylinder which is also provided with openings corresponding to those in the body and shaped differently shall be inserted; this cylinder, by turning, partializes the body openings, varying the ratio of flow of the two fluids. The rotation of the cylinder can be performed manually by a knob or automatically slaved at the wobbemeter or calorimeter, at a fixed position to obtain the mixing ratio of the two fluids. Inside the movable cylinder, with vertical movement, the piston slides. The membrane sensitized by the pressure of the mixture, moves the piston in position, such as to satisfy the required flow rate.

| sm3/h | mbar | kCal/sm3 | ||

| injector SYSTEM | ||||

| Villafranca del Penedes (E) | GN/Aria NG/air | 4000 | 150 | 4.900 |

| Zaragoza (E) | GN/Aria NG/air | 6000 | 150 | 3.800 |

| Vendrell (E) | GPL/Aria LPG/air | 750 | 50 | 4.500 |

| Castelnovo Ne' Monti (I) | GPL/Aria LPG/air | 2300 | 25 | 9.100 |

| COMUNE di Sannazzaro de' Burgondi (I) | Gas Raff./Aria Uncondensable Gas/air | 2500 | 470 | 12000 |

| Aria propanata Propane/air | 2500 | 430 | 12000 | |

| COMUNE di Rho (I) | GN/Aria NG/air | 1500 | 16 | 4500 |

| 4000 | 16 | 4500 | ||

| CAMUZZI GAZOMETRI spa ALASSIO (I) | GN/Aria NG/air | from 2500 to 3600 | 80 | 4200 |

| AZIENDA MUNICIPALE GAS Palermo (I) | GN/Aria NG/air | 11.000 | 30 | 5750 |

| ILVA spa GENOVA (I) | GN/Gas AFO NG/gas blast Furnace | 26400 | 38 | 6900 |

| BLOWN AIR SYSTEMS | ||||

| PHILKERAM sa SALONICCO (GR) | Butano/Aria Butanr/air | 1800 | 2.000 | 12800 |

| COMUNE di Sannazzaro de' Burgondi (I) | Gas Raff./Aria Uncondensable Gas/air | 3700 | 600 | 12000 |

| Aria propanata Propane/air | 3700 | 600 | 12000 | |